-

Phone Number

-

Email Address

The implementation of the Lean system Construction provides numerous enhancements and benefits in a wide number of aspects of the company, and, at the same time, At the same time, it shows its usefulness as a key bet for competitiveness.

The planning process of philosophy Lean represents a revolution in the information sector. construction and how projects are organized Architectural Let's Begin!

Content menu:

LEAN Construction is a philosophy of management that seeks to provide value and customer benefits in project planning construction through optimized processes applying continuous improvement.

Its beginnings are the industrial sector at the end of the 20th century with Lean manufacturing and as the main exponent, the Toyota automobile factory that created a management model with the aim of minimizing the losses in products with the minimum amount of resources .

A system based on Lean Production has as objective the elimination of those activities that do not add customer value; optimize and reduce time in the production, reduce costs, improve product quality product , etc. In general, the advantages of apply a Lean process would be:

If we transfer the Lean methodology and techniques to construction sector , is beginning to stand out benefits that Lean implementation can bring Construction in the planning process of a construction site ;

The construction sector has always been very traditional and quite sensitive to new changes or new ways of management. This situation, over time, has caused the works, and in general, all construction processes, have important deficiencies in many respects and that, moreover, they repeat constantly.

The objective of Lean Construction is to minimize risks, be more effective and increase efficiency than translates, and broadly speaking, into benefits for all parties involved in a work, from the beginning in the creation of the project, even in delivery of the same work (Remember article on how to validate projects before starting works).

The way to optimize processes is through detection and elimination of the 8 wastes of the Read :

The Lean requires working methods and tools that facilitate its application, here it enters the Last Planner® System (LPS) is a monitoring method of this planning based in the collaboration and commitment of the subcontractors .

Both in the initial planning and in its weekly follow-up. The application results are very successful, saving time of delivery thanks to the coordination of all the contractors and/or subcontractors through initial meetings ( Pull Planning ) and weekly meetings.

Due to the complexity involved in explaining all the nuances of the Last Planner® System methodology. the next video represents the first part of six videos that explain with detail how it works and its application (The list of reproduction of all the videos can be consulted HERE).

Remember that in our extensive article on houses precast we could already see significant savings in housing execution times.

In Lean Manufacturing (Lean in the industry), cost savings with Lean are achieved practically immediately. There are clear differences between the industrial and construction sectors:

| INDUSTRIAL SECTOR | CONSTRUCTION SECTOR |

| A product is manufactured repeatedly | Each build is a pilot project |

| Low turnover of workers hired by the company company, thus favoring a long-term and instilling the Lean culture. | Each week operators from different companies, with the impossibility of fully integrating them in the Lean culture. |

| Usual collaborating companies. | For each project a company is chosen partner, usually based on cost. |

| Work is done in closed, controlled spaces. | You work outdoors for a long period of time. time in difficult-to-control spaces. |

| The product moves through the factory and the operator it is static. | It is the operator who moves around the building or infrastructure. |

| The product is almost 100% defined before put it into production. | The product is being defined while it is in phase production |

Because of these differences, Lean cannot be implemented the same way in one sector as in another. delete part of waste as excess inventory or overproduction are factors that can be carried out faster in a factory than in construction.

However, the philosophy is the same, and applying tools such as Last Planner System on site , the teams organize and coordinate among themselves, under the leadership of the Site Manager.

Although it is true that with this methodology (LPS) achieve cost savings on site, the true potential is in the drafting phase of project . If we involve the contractors and subcontractors in the drafting phase of the project, we will ensure that the project is designed to put it into production and with an optimal level of detail to build without need to halt production due to lack of definition.

One of the keys in project management is control of the risks and how we should manage them.

In design phase:

In this phase, under the Lean philosophy, the Lean Integrated Project Delivery methodologies (LIPD). At this point, we can get the risks are much smaller, since the 3 parts design thinking about production .

However, under this methodology another type of risks. For example, decision-making among all, coordination of the teams or achieve the cultural change of the participants in the collaborative contract. To do this, read and Lean Construction in particular has created tools that allow us to help like:

Under construction:

In the Last Planner® System (LPS), it is considered a restriction to everything that prevents me from carrying out the activities that generate transformation (formwork, reinforcing, concreting, etc.). Until No systematic method has now been used on site to manage the restrictions (not having the detail construction, lack of municipal permits, lack of personnel or material, etc.).

LPS offers you the restrictions form, where weekly through the weekly meeting, the subcontractors detect everything that is going to be needed to be able to carry out construction activities that begin within 6 weeks.

As a consequence of the application of Last Planner on site… Can the quality be affected? some people They ask if, in order to finish the works faster, the quality has been affected. If we take real data from post-sale that we have consulted, we can say emphatically that NO. Sometimes even the coordination between the unions it can improve the quality of execution.

On the other hand, where great quality can be generated It is in the design phase o. At this point, the contribution of contractors and subcontractors can be key to improve quality.

In Lean quality is not based on inspection but in looking for the absence of error, that is, quality in the origin . For this, there are tools for the generation of anti-error systems called “ Poka-Yoke ”

The 5 S's application represents a very useful tool useful. These are 5 words that start with “s” in Japanese. It is a methodology that makes you follow sequentially the different "eses" to reach the objective to create orderly workspaces and cleanliness that help eliminate waste and create safe work spaces.

It is certainly easier to apply in a static environment like a factory or an office, than in a construction site, but it is You can and we can see it in the following video…

“ What is not measured cannot be improved ” phrase attributed to Peter Drucker that makes sense in the theme that we address. Lean seeks perfection, so you have to apply the “Kaizen” or continuous improvement . But for it it is necessary to measure and obtain reliable data and key indicators that help us improve.

There are several key indicators within Last Planner System as:

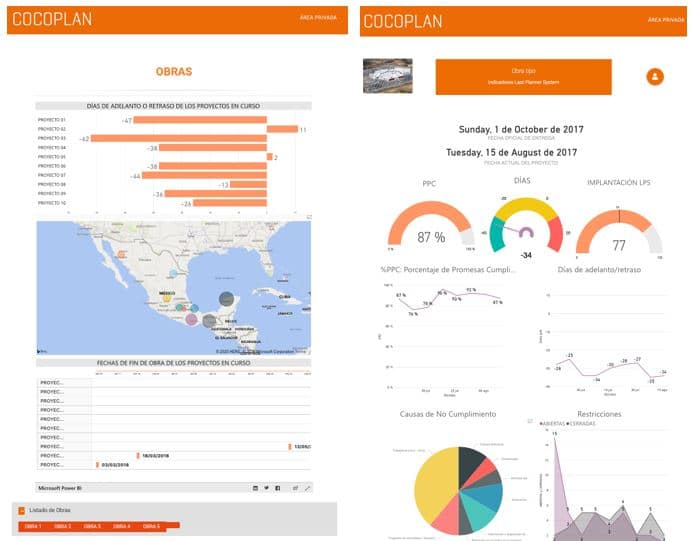

In order to obtain the data and be able to handle it, They use different software. We know the COCOPLAN because some colleagues use it and recommend it, we suppose that in the Spanish-speaking market there will be others.

Other software to handle daily work as technicians We commented on it in the article on management of works and reforms to the complete.

So far, we have mentioned the advantages of apply Lean in the construction sector , but especially in projects. Once the effectiveness has been proven of philosophy through some of its methodologies and/or tools, fundamentally Last Planner for construction companies , companies tend to want to convert your organization into a Lean company, a Lean Construction Company .

There are countless companies that apply this philosophy To be successful, they try to generate the most value by client, eliminating everything that does not generate value and applying continuous improvement in search of perfection, to that your customers are as satisfied as possible.

To achieve this objective, it is necessary to transform the way of think of each and every one of the workers and providers. However, Lean offers you a number of methodology and tools that allow us to carry it out.

Probably at this point one is already aware that Lean takes people into account and makes them participate in each action . Indeed, Lean is I also respect people, they are taken into account and In addition, it makes your motivation greater.

It is evident that with one article it is impossible to detail all the steps, but to fully understand how does the Lean Construction methodology work we want provide a video that corresponds to an online Masterclass organized by Think Productivity where all the step-by-step planning points.

The success factors in a project are focused on the management of people, in a Strategic Plan, in a focus on the process and the correct management of knowledge and the technology . Any new methodology involves challenges and constant barriers. The following table analyzes the importance of highlights: