Micro-cogeneration facilities. Analysis, components of an installation, videos and legislation.

Content menu:

- Definition and application of micro-cogeneration:

- Most outstanding advantages of the installations of micro-CHP:

- Some criteria to consider in the design of the installation.

- Explanatory videos of its operation:

- Application Ordinance:

Definition and application of micro-cogeneration:

They are small power equipment of up to 50 kW that are They are easy to install and do not necessarily require a large investment, mainly applied to buildings industrial, tertiary use as well as residential. It is about of a technology called generation distributed that is also characterized by allowing the production of electrical and thermal energy with high savings in the consumption of primary energy, since the losses of electrical energy from the transport and distribution of electricity.

The micro-cogeneration equipment are modules that allow the simultaneous generation of electricity and heat for heating and ACS from the primary energy of a fuel , it is highly efficient equipment consisting of an electricity generating system with the additional capacity to take advantage of the residual heat of the process to generate thermal energy. Micro-cogeneration is based on three types of technologies that are the engines of internal combustion, those of external combustion of the Stirling type and microturbines.

They are configured as an effective alternative to improve the energy efficiency of both buildings and homes considered individually, since they constitute an option technique that is easy to implement, economically viable and very efficient especially in ACS and heating installations centralized.

Most outstanding advantages of the installations of micro-cogeneration:

- This is a system that is currently manufactured in compact format similar to that of a conventional boiler, which is capable of simultaneously generating electrical energy and thermal energy , without requiring a lot of space for installation.

- Currently for the micro-cogeneration are used both Fossil fuels (natural gas, butane, propane, etc..) like other fuels such as biodiesel, which have low emission of gases in its combustion and for its ease of production from plant products; although they are investigating systems that they use for their operation renewable energies such as biomass and solar energy.

- Although its price is higher than that of a unit or boiler conventional, are amortized in less time because achieves greater energy savings by reducing significantly primary energy consumption (may reach up to 40%) and CO2 emissions and also the maintenance and operating costs are lower.

- High level of energy efficiency, with about very high yields of the order of 85-90%, being the team that comes closest to achieving the theoretical cycle of Carnot.

- The cost of the initial investment is reduced when These are installations in buildings that exceed a number of dwellings in centralized systems, when compared to other similar equipment or facilities .

- Allows automatic regulation so that it will start and will stop depending on the energy needs that specify the building at all times, so that your yields are linked to the demands being able to say that the higher the demand, the higher the performance and the higher the efficiency energy, these systems will work with better results in areas with colder climates, especially when compared to others of solar energy that in this type of climate reduce their yields greatly.

- These are highly reliable equipments that work reliably silent by the simple and straightforward nature of its mechanics, which also helps to reduce the risk of breakdowns as well as oil consumption and reducing the friction losses inside.

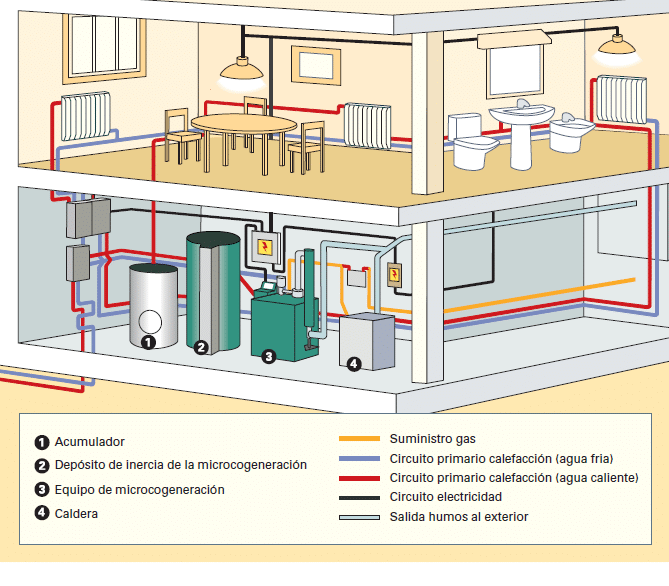

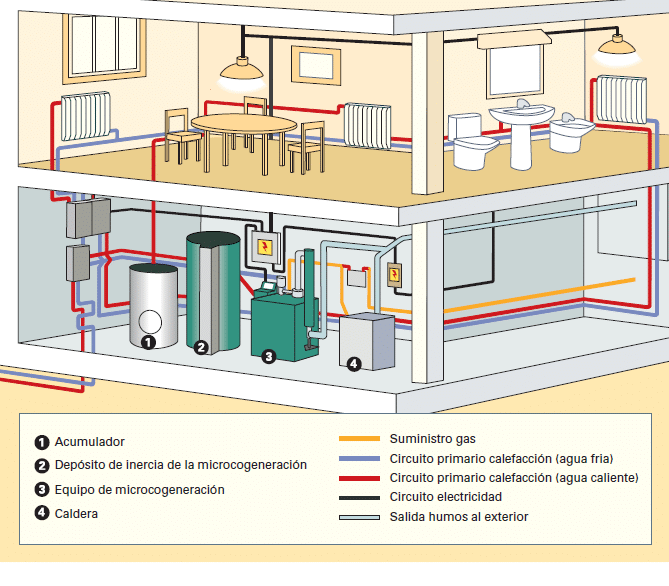

The following image details the components of a micro-cogeneration installation:

Some criteria to consider in the design of the installation.

The basic criteria to take into account when designing a micro-cogeneration facility are the number of hours of operation, together with the thermal demand user, emissions and operating costs. Must be consider that the longer the operating time of the equipment the initial investment will be recovered sooner as a result of the largest amount of energy produced, so its economic profitability increases, requiring a high thermal demand to be profitable.

When choosing these systems it is advisable to with precision an adequate design, calculation and sizing of the installation in order to get the best performance from the itself in the best possible conditions of operation.

Explanatory videos of your operation:

This IDAE video explains what the cogeneration, its advantages and an application case is mentioned in a 97-unit building in Colmenar Viejo (Madrid):

This second video explains in more detail how the brand's micro-cogeneration boiler model works ecoPOWER:

Application Ordinance:

Applicable legislation at the Spanish and European level about micro-cogeneration is the following:

- Directive 2004/8/EC , relative to the promotion of cogeneration based on the demand for useful heat.

- RD 616/2007 of May 11 , on the promotion of high-efficiency cogeneration.

- RD 661/2007 of May 25 , by which regulates the activity of energy production electricity in special regime and that replaces the Real Decree 436/2004 of March 12.