-

Phone Number

-

Email Address

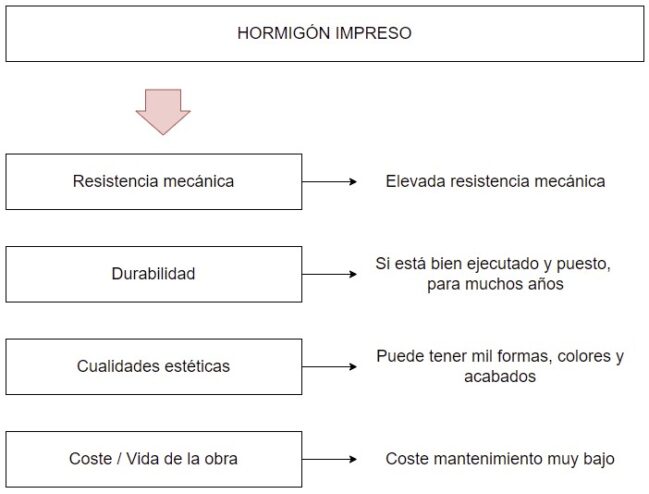

Within the wide range of constructive possibilities in which comes into play concrete and its different applications, there is concrete printed (also commonly called pavement printed and wrongly assigned with the name of « printed cement » being that they are concepts different).

To understand stamped concrete; what is it, what is it for, types, colors, where it is placed or why it is used. First we need to review what is concrete .

Concrete or concrete (in South America) is a constructive material where different items; a binder (which is usually Portland cement), aggregates (sand, gravel, gravel, etc), water and some specific additives (See examples of houses with concrete).

By combining them, according to proportions and properties, we have a construction material with excellent performance determined, which, moreover, in a general way, is malleable , has characteristics adherents and is greatly hard .

Starting from here, an aesthetic alternative to the traditional decorative architectural materials used in outdoor paving such as; wood, ceramic, terrazzo, etc. New techniques and systems constructions that represent imitations of materials nobles .

The use of fair concrete for paving outdoor (mainly on outdoor floors or exposed to climatic conditions) is another aesthetic option to the materials that resembles, but, has peculiarities and This is what we are going to discover in this article.

Content menu:

It is defined as concrete pavement printed to the decorative technique that results from apply a continuous hardening mortar made in situ , usually colored, on a surface of fresh concrete. The subsequent texture, reliefs, stamped, are with molds of different shapes and designs, and the application of the final product and protection (which is a resin).

The resulting hardened mortar will give us appearance similar to noble materials such as slate, stone, slate, paving stone, ceramic tiles, wood or, practically, any other with varied geometric shapes (See also types of laminate flooring and which one is better).

To understand specific stamping from a schematic perspective, we leave the two cases more generals with their main layers; when we have no base and with base - screed on consolidated soil.

It is not a new coating mortar, it already has years of use. baggage, and is a material par excellence in concrete floors. many public places ; on walks, sidewalks, roads, streets, squares, urbanizations, etc. But its usefulness too has been moved to the outside of buildings , in their common areas, or especially in homes single-family houses (chalets) as a covering of terraces, porches, paths, in short, outdoor areas or the edges of swimming pools (in the latter, care must be taken due to the ph – chlorine in the pool)

Although it has some advantages, it must be said that we never will provide the true aesthetics of a noble material such as stone or wood, or the possible perfectionist finishes of a Good precast ceramic or terrazzo tiles, you have to have it! note!

The pigmented concrete in which the a reticle while fresh that simulates pieces and textures of other materials. It requires a lot of specifications techniques in cases with significant wheeled traffic or sunsets special (later there is a guide for this purpose)

The market offers for sale a great variety of grids, flat templates with relief and molds (metallic – polyurethane) with solutions, dimensions and thickness different; small, large, rectangular, oval, arched, herringbone, etc., which are obviously symmetrical and we can replicate them to our liking. The types of molds for stamped concrete the most common are:

Image above represents polyurethane insoles that are much less heavy and easy to use when printing a texture to make them look like imitations. There's also solutions with reliefs like the following image or coarser with an edge to simulate stones on a path.

Some professionals refer to a “dye” (substance soluble) to the product that colors the mortar when we practice the stamped concrete , but, in reality, the technical description is pigment (insoluble substance).

There is a wide range of coloring products of cement and concrete which in turn provides a complexity when obtaining a certain color (See article color in architecture). always have to do previous rehearsals to see the final result or we can get a good scare and not get the color you want the client.

The pigments can be natural or artificial . That usually go with colors from green, organic blues, yellows and reds ideal for interiors and, black, red, yellow, gray, brown, green and blue inorganic for exteriors.

For stamped floors on site and construction, artificial ones are normally used – inorganic and within this palette, the most recommended are iron oxides synthetics .

To color cementitious products that we will use outdoors we have limitations that mark us the different shades of pigments that we can use (Technical guide here). In the following image we have the palette of synthetic colors that we can use:

There is no work or constructive element that is perfect and in most cases, the economic investment (paying more or less, both in the work of the operators as in materials) largely determines the service life of the executed work.

| Printed concrete advantages | Disadvantages of stamped concrete |

| Multiple layouts | Skilled labor needed |

| Fast Execution | Expensive repairs |

| Lower price compared to materials traditional | Be careful with the release agent and sealer |

| Prevents weed growth | Cracks |

| Little maintenance requirements | Not suitable for extreme environments |

| Long service life | Watch out for drainage |

| Specific breaks | Beware of hidden elements |

Actually, here we can spend hours arguing in a very broad market, with multiple companies specialized in its placement and without counting on the demands or the budget of the client, surface or accessibility.

What we are clear about is that the budget must go square meter executed (labor and materials) and finished (in the case of curbs, it is usually budgeted for linear meter).

To make a comparison that enters into a reality coherently we have addressed the Price Base of the Construction published by the IVE for this year. the average price with a thickness of 14 centimeters, mesh and fibers of polypropylene, it costs us 28.27 Euros per square meter including workmanship:

There are cases that will offer us with a thickness of 10 cm (We have seen some offer for 20 Euros/m2) instead of the 14 cm indicated in the image. It is very convenient to use a mesh – armor Do not put stamped concrete without a armor! (We will explain later)

Remember that we wrote an article about a tool of the IVE on how to pre-calculate costs execution of actions urban.

Although the execution process of the printed paving is relatively quickly, obviously, we will have to follow a few steps and control the times, both for an adequate adherence as a homogeneity in color.

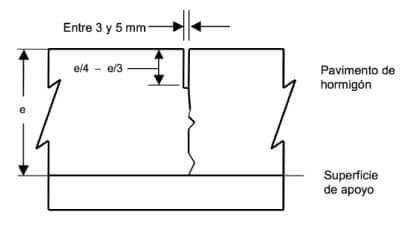

From a technical perspective, concrete floors and choosing it requires professional knowledge and this consultation guide (download in PDF for free, if we registered) on continuous pavements with concrete (Spanish regulations apply) will help us to correct choice according to road and other technical aspects of importance.

Given the great diversity of solutions and finishes, with joints that can respond to the same service situation, defines an identification code that is indicative of the characteristics of the same directly related to the use to which he will be subjected.

Now, we leave an infographic of the manufacturer Sika to see step by step the placement procedure in situ so overall:

And to see it from a visual perspective, we leave a video fairly detailed system and execution process stamped concrete with some useful tips:

With the right tools, installation won't be a chore. problem in the hands of specialists. The paving is manufactured directly on the site and continuously. It is not limited your placement on sloping or uneven floors, where other materials would not adapt (Of interest the article on mosaic floors and hydraulic tiles)

In addition, we want to add some useful tips from Pavistamp in its guide to selling materials on the start-up work of colored mortar for concrete stamping , powder release agent (Prevents the mortar sticks to the mold) and on the protective resin:

| Mortar Application Tips colored |

| The base where we want to pave will be duly compacted and clean, with the approval of management optional, to receive the concrete. thickness in In all cases, it will be decided by the construction management or the property. |

| Avoid concrete with excess additives, hinder the rise of water by capillarity preventing the hitch – grip between the concrete and the mortar. |

| In printed pavements, in light tones, avoid the application on fresh concrete with excess water by capillary rise, apart from increasing consumption (3-4 kg/ m2), we have loss of resistance and the consequent discoloration of the pavement once dry. |

| Do not add water to the product once it has been sprinkled over the fresh concrete. |

| Avoid application with direct and strong insolation wind. |

| Release application tips on dust |

| Manual dusting in plastic state. |

| Apply in one layer covering the entire surface. |

| Avoid application when concrete has excess of water on the surface, since zones would be formed whitish very difficult to control. |

| Do not apply in strong wind. |

| Resin application tips protective |

| On cementitious bases: <4% humidity. |

| Supplied ready to use. |

| No additives need to be added to the resin when we apply to decorated floors. |

| Indoors, apply with adequate ventilation. |

| During work and application use gloves, mask and safety glasses. |

| Do not apply with frost, risk of rain, humidity or direct insolation. |

| Application temperatures between 10-25ºC (measured on the pavement). |

| Can be used over time for the conservation and maintenance of any soil concrete, whether smooth, decorated or with prominences. |

For the reinforcement and improvement of the different characteristics of the concrete pavement, the mesh is used (lattice made of metallic materials) or steel fibers (there are also of other materials, for example, macrosynthetic fibers)

Although each professional has their opinion, we contribute the following scheme that compares the mesh with the fiber of the Obralia company:

We find the contribution of the fibers quite interesting about concrete and its advantages. Although it must be emphasized that there is an important range of fibers and you should always consult professionals to choose the most coherent according to needs.

In one article it is impossible to detail all the systems and technical aspects of the wide world of concrete printed matter , the varieties of materials and putting into work with different punctualities. We just wanted to give a general review and that can add value.

This technique has been used for a long time and is therefore Therefore, there is great experience in the market. The best advice is look for different budgets and always in companies that have Demonstrable projects that we can test.

If you liked the article, rate it and share!